The Power of One: Redefining Quality in Digital Manufacturing Through Single-Contract Procurement

How a single contract can simplify complex procurement by centralizing responsibility and ensuring consistent quality.

Whitepaper Foreword

The Shifting Landscape of Manufacturing Procurement

Recent events such as the COVID-19 pandemic, ongoing geopolitical tensions, and an increased focus on sustainability are redefining how companies approach procurement. In the current scenario, organizations not only have to prioritize cost-efficiency but also implement supply chain resilience, operational flexibility, and environmental responsibility in their procurement strategies.

Adding to the complexity is a shortage of skilled labor in the engineering and procurement sector. In fact, industry reports forecast that the global manufacturing industry could face up to 2.1 million unfilled positions by 2030.

The Rise of Digital Manufacturing Platforms

Today's procurement professionals are expected to balance speed, convenience, and consistent quality. Traditional procurement systems, with their time-consuming manual processes, can't keep pace. They also fall short when it comes to scalability and flexibility, which are required to accommodate market changes or disruptions.

Digital manufacturing platforms are the answer. By digitizing and automating workflows, they offer a faster turnaround. These platforms provide access to a large network of manufacturing capabilities, ease of scalability, quality assurance, and reduced administrative work. They're equipped to handle a wide range of needs. Whether it's a one-off 3D-printed prototype or full-scale series production. Digital manufacturing platforms also streamline the process by handling communication, compliance, and quality under a single contract. This eliminates the need for buyers to manage multiple vendors, which reduces the workload on internal teams.

Such platforms are valuable for lean engineering and procurement teams, allowing them to focus on core functions like product development and project planning.

Scope of This Whitepaper

This whitepaper draws from market research and FACTUREE’s industrial procurement survey to explore how shifting market demands are redefining the procurement landscape. We will explore:

Why traditional procurement methods are struggling to keep up with the modern manufacturing landscape.

How digital manufacturing platforms are enabling efficient, resilient, and scalable sourcing.

Whether digital platforms can consistently deliver high-quality parts with their distributed network of suppliers.

What customers think about these platforms, including benefits and challenges.

An in-depth look at FACTUREE’s single-contract model and how it simplifies procurement while ensuring high quality.

Addressing common misconceptions about digital procurement.

The New Procurement Reality

Changing Dynamics and Challenges

Digital manufacturing platforms are rising to the modern procurement challenge. However, to become a reliable long-term solution, these online services must do more than just deliver parts. They must stay current with the following industry trends that are shaping the future of manufacturing.

Speed: Getting to Market Faster

Speed has become one of the most significant pressures in modern manufacturing. Companies that can launch new products quickly are better positioned to capture market share, respond to customer feedback, and stay ahead of competitors. In sectors such as consumer electronics and automotive, rapid time-to-market is a must.

Procurement plays a crucial role in making this possible. Sourcing parts from CAD drawings quickly at competitive prices is necessary to avoid bottlenecks in the production pipeline. Delays at the sourcing stage can slow down production lines, delay product launches, and impact revenue goals.

As a result, manufacturers actively seek procurement partners who can deliver high-quality components on tight deadlines. Digital manufacturing platforms address this by automating certain aspects. This includes using AI-powered analytics and historical data for supplier matching to reduce lead times.

Flexibility: Scaling and Adapting with Ease

In light of the volatile market conditions of recent times, flexibility has become a necessity for manufacturers. These companies need the means to scale production in response to fluctuating demand. They should also be able to incorporate design changes even at late stages without much hassle.

Traditional procurement setups meant for predictable environments and long product life cycles are not equipped to handle these requirements. Risks of supply chain delays and raw material shortages have made adaptability crucial. Digital manufacturing platforms make this level of flexibility easily accessible. Leveraging agile sourcing strategies with access to a diversified supplier base, online procurement platforms can quickly switch to alternate vendors.

Resilience: Preparing for the Unexpected

The COVID-19 pandemic exposed the overreliance on a single source or region for procurement. The ongoing conflict between Ukraine and Russia is also affecting raw material availability and transportation routes. Even isolated events, such as the Ever Given container ship blocking the Suez Canal, have shown that a single point of failure can disrupt global logistics.

As a result, resilience is no longer an afterthought. Companies are actively reevaluating their product sourcing strategies. There is growing recognition that procurement models need to integrate supply chain diversification and visibility to mitigate risk.

Digital manufacturing platforms are playing a critical role in this shift. By providing access to large, vetted networks of suppliers across multiple regions, these platforms allow companies to build redundancy into their sourcing. Companies that proactively invest in adaptive and distributed sourcing models are better positioned to withstand the next disruption or even a black swan event.

Skilled Labor Shortage

In addition to external factors such as supply chain disruptions and geopolitical instability, companies are also grappling with a shortage of skilled labor. This impacts the manufacturing industry more significantly than other sectors because production jobs typically require specialized technical skills and on-site work. In 2022, a survey by IFO found that 57% of metalworking companies in Germany were facing operational challenges due to a skilled labour shortage. It predicts that the problem is likely to intensify as the working-age population is projected to shrink by 10% by 2050.

Recruiting and retaining qualified engineers and procurement specialists has become increasingly complex. Several factors contribute to the shortage, such as an aging workforce and a lack of flexible work options. A recent report found that three in five young people are unlikely to consider manufacturing careers. Hiring gaps mean smaller teams are expected to handle more complex tasks. With fewer hands on deck, errors become more likely. In the context of procurement, digital manufacturing platforms can help companies maintain efficiency despite these constraints. These platforms can reduce administrative burdens by streamlining workflows and automating repetitive tasks.

Key Takeaways from FACTUREE's Industrial Procurement Survey

To better understand the changing face of procurement and the needs of their customers, FACTUREE conducted a survey involving 181 industry professionals. Respondents included managing directors, procurement managers, engineers, and technical project managers from industries including automotive, aerospace, medical technology, and consumer goods.

The results reflect a growing acceptability toward digital parts procurement strategies across industries. When asked whether they would consider using digital manufacturing service providers, 43 percent of respondents said they would use them as substitutes for their existing suppliers. Another 44 percent said they would consider digital providers as their primary suppliers.

This increasing preference for digital procurement reflects a trend toward process efficiency, transparency, and flexibility. Digital platforms optimize workflows by reducing administrative overhead.

Price is another important factor when buyers and engineers evaluate new suppliers. This is particularly relevant in the current challenging economic situation. Digital procurement platforms enable quick comparisons, helping customers find competitive pricing without compromising on lead times. In essence, the transition to digital procurement is not just about convenience. It reflects a strategic decision toward achieving speed, flexibility, and resilience.

Challenges to Digital Adoption

While digital procurement offers many benefits, it is not without its fair share of challenges. The survey results indicate that several concerns hold companies back from fully embracing digital sourcing models. For 38 percent of survey participants, quality issues are the primary concern. This highlights an ongoing perception that digital manufacturing platforms may struggle to consistently meet strict quality standards. Intellectual property (IP) protection also emerged as a significant concern, with 32 percent of respondents expressing concerns about data leaks. Lack of transparency was cited by 28 percent of participants.

Perceived higher costs (28 percent) and longer delivery times (25 percent) were also identified as potential drawbacks. Data privacy and security were flagged by 23 percent of respondents. This indicates that the hesitancy to share procurement data remains a worry. Lastly, lack of certifications was a concern for about 23 percent of respondents.

These findings highlight that while companies seek faster and more flexible sourcing, they are not willing to compromise on quality and reliability. At the same time, price remains a key consideration.

Value of efficient and adaptable procurement models

Despite the concerns, most survey participants were optimistic about the benefits of digital procurement platforms, especially in terms of accessing an extensive supplier network through a single contract. This model offers a streamlined alternative to the traditional approach, where companies have to manage multiple suppliers on their own.

In the survey, 40 percent said it was "very helpful" in reducing administrative workload and simplifying supplier management. Another 41 percent found it "somewhat helpful" for streamlining procurement processes. For many procurement teams operating under tight deadlines, accessing a supplier network through a single contract frees up significant resources.

Only 4 percent were critical of the model, highlighting concerns about reduced transparency and less direct control over supplier selection. These respondents felt that using a supplier network may lead to less visibility into raw material sourcing, quality practices, and tracking.

Overall, these results show that companies recognize the value of efficient and adaptable procurement models. In particular, the single-contract model stands out by streamlining operations with centralized communication and performance monitoring.

Looking ahead, the upcoming Carbon Border Adjustment Mechanism (CBAM) will require all companies manufacturing goods outside the EU for import into the European Union to report the CO2 footprint of their production and supply chain. This adds to the administrative complexities, which can cause delays in project timelines. But since FACTUREE is headquartered in the EU and can source within the region, its customers are saved from the hassle of CBAM altogether. For deliveries from outside the EU, FACTUREE takes care of all formalities, including customs, documentation, and regulatory compliance. The source and CO2 data for every component are precisely tracked, verified, and reported within clear timeframes.

FACTUREE’s Solution

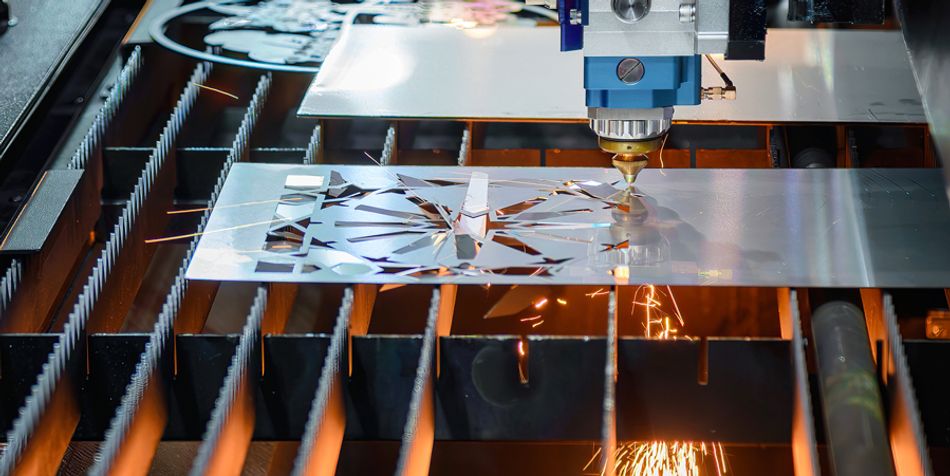

With a single contract, FACTUREE provides access to a wide range of manufacturing services including CNC machining, sheet metal processing, and 3D printing. Through a network of over 2,000 vetted production partners, it also offers one of the broadest material selections in the market.

Unlike typical digital platforms that feel opaque, FACTUREE assigns each customer a dedicated contact person. This allows customers to build a long term relationship, similar to what you'd expect from a local supplier. These experienced contacts are well-equipped to help you choose the right manufacturing process and materials based on your technical and budget requirements.

The FACTUREE team is available for free, bookable consultation calls to support potential customers early in the process. Submitting a request is easy and convenient. You can either use the online request tool or send your inquiry by email. FACTUREE takes care of the rest by guiding you through the process.

Here’s a look at some processes FACTUREE has in place to address common concerns associated with digital manufacturing platforms.

Smarter Costing with AI

Many companies use the 'should costing' method, which estimates what a part should cost if it were produced under optimal, efficient conditions. While it offers a transparency cost calculation, it falls short when it comes to drawing-based parts. Even minor deviations or slight changes in the drawing can lead to entirely different production requirements and costs. Therefore, calculating target costs in a standardized way doesn;t make sense in this context.

FACTUREE takes a more advanced approach to target costing. Instead of relying on static models, it uses a combination of its data-driven, AI-supported system. The company not only analyzes customer drawings down to the smallest detail, but also determines the best possible price across its supplier network. FACTUREE custom-built AI software simulates requesting quotes from every potential supplier. This is essential because pricing can vary significantly between partners based on their capabilities, machinery, and current capacity. This approach also minimizes the risk of errors right from the start and guarantees that parts are produced by the best manufacturing partners.

Over the past six years, FACTUREE has collected over 600,000 data points per supplier. This extensive knowledge base allows the company to predict reliable target costs with a level of precision that traditional instant pricing tools can't match. As a result, customers often achieve significant savings of over 20 percent in procurement costs

Rigorous Supplier Vetting and Monitoring

FACTUREE thoroughly evaluates manufacturers to ensure they have the right machinery and skilled workforce to handle complex parts and high volumes. This is especially critical for processes like CNC milling where tolerances often need to be as precise as ±0.01 mm. New partners start with smaller test orders to prove their reliability and quality in practice before taking on larger projects. This phased approach helps build trust and ensures consistent performance.

By implementing clear quality guidelines, the company ensures that only suppliers with a proven track record for precision, reliability, and timeliness become part of its distributed network. Each new manufacturer is then assigned a dedicated FACTUREE buyer. This "mentor" closely guides the new partner, assists with questions, and ensures smooth integration.

Quality control does not end after onboarding. FACTUREE continuously monitors the performance of its manufacturing partners through a dynamic rating system that updates with each completed project. This system considers factors such as manufacturing precision, timeliness, and client feedback. This continuous monitoring process ensures the supplier base remains competitive.

Layered Approach to Quality Inspections

Once a part is manufactured, it undergoes a two-step final inspection process. First by the manufacturing partner, followed by FACTUREE's quality control team with zero tolerance for defects. Customers also get the option to receive production samples in advance to verify quality. This layered approach ensures that every component meets your exact specifications in series production. By implementing this rigorous quality check, the company guarantees that customers receive defect-free parts irrespective of the order volume.

FACTUREE supplies inspection reports such as 3.1 material certificates for a nominal fee of under 30 euros. First Article Inspection Reports (FAIRs) and detailed measurement reports can be generated internally or through certified external partners as per customer requirement.

Capacity and Material Diversity You Can Count On

FACTUREE's large manufacturing network, with over 2,000 partners across regions, comes with significant benefits. One of the biggest benefits is virtually unlimited production capacity. This allows customers to ramp up or scale down quickly based on project needs. This flexibility leads to stronger supply chain resilience. If a disruption occurs due to natural disasters, geopolitical tensions, or trade wars, production can be moved to a different region. In traditional procurement methods, this would require investing time and money to onboard new suppliers.

A large supplier network also offers greater flexibility in choosing manufacturing technology and materials. This allows it to serve a wide range of industries. For example, biocompatible materials are essential in the medical device sector, while aerospace manufacturers rely on heat-resistant alloys that meet the standards. By centralizing access to such a diverse material catalog, FACTUREE eliminates the need for customers to manage multiple suppliers, coordinate logistics, and align quality standards across vendors.

Building Buyer Confidence

In a FACTUREE survey, 38 percent of participants cited quality as a barrier to adopting digital manufacturing services, followed by 28 percent expressing worry about transparency. These concerns may stem from assumptions that distributed manufacturing means reduced oversight and inconsistent results. FACTUREE’s digital model disproves those notions. The company doesn't simply connect buyers to suppliers on its platform. Instead, it takes responsibility for the entire procurement process, including quality assurance, compliance, and timely delivery.

Unlike traditional sourcing, which can vary widely in documentation and compliance standards across suppliers, FACTUREE ensures consistency through its approach. Its internal quality management system is ISO 9001 certified for reliability. This is particularly crucial when sourcing components for applications where minor defects could result in major risks or costly recalls.

Additionally, FACTUREE’s dedicated project managers allow for long term collaboration built on trust. They take the time to understand customers' needs in detail and offer in-depth consultation. It could be anything from choosing optimal material or the ideal manufacturing process for a project. By combining the broad supplier network with centralized quality management, FACTUREE delivers a procurement model ideal for today's industry dynamics.

Security as a Core Priority

Traditional request for quote (RFQ) processes often require companies to distribute sensitive design files to multiple vendors just to receive pricing and delivery estimates.This increases the risk to intellectual property. The situation becomes trickier in the case of international supply chains. due to the wide variation in regulations across the globe.

According to Christopher Walzel, CPO and Co-Founder of FACTUREE: "The best data protection is not to disclose your sensitive data to the outside world in the first place." This Principle is part of the FACTUREE strategy. During the quotation phase, the platform does not share CAD drawings with potential suppliers. Instead, it relies on historical data and proprietary AI algorithms to generate price estimates. This approach adds another layer of protection beyond the NDAs already in place with its partners. Unlike traditional tender processes where vendors know the end client, FACTUREE maintains anonymity. Even when an order is confirmed, the design data is shared with anonymity. For both customers and manufacturing partners, FACTUREE acts as the sole contractual partner. This arrangement also holds true in the event of defects; FACTUREE assumes full responsibility and warranty for all delivered parts to the customer.

Furthermore, FACTUREE relies on ISO 27001-certified data centers located in Europe. These facilities comply with strict international standards for information security management. By embedding security at every layer, FACTUREE eliminates one of the key barriers to adopting digital manufacturing.

Conclusion: Quality as a Strategic Differentiator

It's easy to assume that rapid procurement and quality cannot exist together. However, digital manufacturer FACTUREE is turning this assumption on its head. Rather than accepting lower standards, FACTUREE is demonstrating how digital platforms can use advanced technology to deliver quality.

With the combined use of AI, data analytics, and human expertise, FACTUREE ensures that each order is matched with a partner capable of handling the job requirements. This smart distribution model sets an example of how digital tools, when properly implemented, can improve the quality of results.

FACTUREE's QA ensures that parts are manufactured according to exact specifications. The supplier inspects every part before shipping. Another inspection at FACTUREE's hub follows this. Additionally, FACTUREE offers third-party inspections for critical components used in the healthcare, aerospace, and automotive industries.

Learn more about how FACTUREE's three-stage quality assurance system is setting new standards for online manufacturing.

If you'd like to discuss your specific requirements, you can schedule a trial project consultation before requesting a quote.