The Future of AI-based Engineering Design: From Code Generation to Predictive Maintenance

AI is transforming engineering by enabling professionals to express system development goals in natural language, which AI can then convert into code, designs, or strategies. This shift is democratizing access to advanced engineering tools and boosting productivity.

Introduction

In less than three years since the arrival of ChatGPT, there has been a surge of interest in Large Language Models (LLMs) and Generative AI (GenAI). Hundreds of AI applications are rapidly transforming various areas of the economy, including finance, marketing, manufacturing, and other industrial sectors. The advent and widespread adoption of Generative AI is giving rise to a new computing paradigm, namely AI-based “intent computing”. In this paradigm, AI is transforming how multimedia content and software are written, but also how applications and systems are conceived, designed, and maintained.

Engineers can now articulate their system development goals in natural language, letting AI translate these intentions into actionable code, design blueprints, maintenance plans or system development strategies. This shift is already democratizing advanced engineering capabilities, as it makes them available to a broader range of professionals and organizations. At the same time, it is increasing the productivity of industrial organizations, which can now do more in less time and with improved quality. To better understand this productivity revolution, it's best to look at some of the most prominent engineering capabilities that are disrupted by AI technologies.

Writing Original Software Algorithms with AI

One of the areas that has been disrupted by GenAI is software development. Specifically, modern Generative AI tools enable a new approach to coding, where a considerable amount of code is produced by AI tools. AI-generated code can be later integrated into human-generated code to enable the development of larger scale software systems. In this way, software developers increase their productivity and become capable of implementing systems of increased complexity in less time.

During the last year, AI tools have also enabled new forms of software development, where business users develop simple applications and Minimum Viable Products (MVPs) without any programming knowledge. This paradigm is commonly known as “vibe coding” and is currently applicable to small scale applications without complex non-functional requirements (e.g., sophisticated security requirements). Nevertheless, the possibility of vibe coding more complex applications in the future cannot be ruled out.

The Rise of AI Coding Assistants

The above-listed capabilities are enabled by a wide range of AI-powered coding tools such as GitHub Copilot, OpenAI Codex, and Cursor AI, which are rapidly gaining traction. These assistants leverage large language models trained on vast repositories of open-source code, which enable them to suggest code snippets, complete functions, and even write entire algorithms based on developer prompts. The result is a significant reduction in manual coding effort and a boost in productivity.

Enhancing Developer Productivity

Modern AI coding assistants go beyond simple conventional coding completion functions. They offer features like intelligent refactoring, automated code documentation, and test generation. These capabilities accelerate development cycles, while at the same time improving code quality and maintainability. With AI-assisted coding, engineers benefit from faster iteration, debugging help, and the ability to focus on higher-level design challenges rather than repetitive coding tasks.

Lowering the Entry Barrier

AI-assisted coding is the natural evolution of no-code and low-code platforms. Nowadays, these platforms are often powered by AI towards lowering the barrier to entry for algorithm development. Engineers without deep programming expertise can now create functional algorithms using intuitive interfaces and guided workflows. This accelerates rapid prototyping and innovation cycles, while at the same time enabling teams to test ideas and iterate on designs with unprecedented speed.

During the last couple of months, there are also business users that test alternative software development scenarios using “vibe coding” i.e., without writing any code themselves, but rather delegating code development to a Generative AI system like lovable.dev. This has significantly lowered the time and cost needed for developing an MVPa. While video coding is still not adequate when it comes to writing enterprise software at scale, this could change in the future as AI research evolves towards AGI (Artificial General Intelligence).

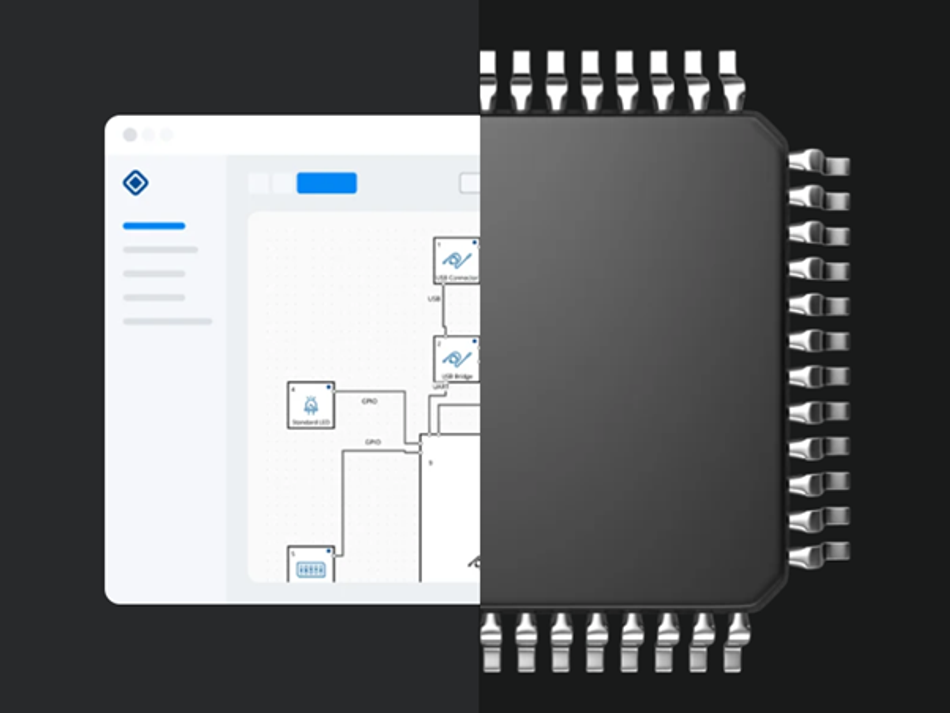

AI-Assisted Product and Component Selection

Selecting the right components from millions of available electronic parts has always been a daunting challenge for engineers. This is mainly due to the sheer volume and complexity of choices considering the variety of components and their unique specifications, tolerance and intended applications. In this context, engineers must balance performance with cost based on the resolution of trade-offs between optimal technical specifications and project budgets. At the same time, it is important to consider availability, reliability, resilience and supply chain issues.

Nowadays, AI-driven platforms like CELUS are used to automate the transformation of technical requirements into schematic prototypes. Similar AI-based selection functionalities are also offered by tools like the Altium Designer PCB design software and Siemens Xpedition (Mentor Graphics). These platforms can generate ECAD schematics and bills of materials with minimal manual intervention. Moreover, they provide real-time component recommendations and integrate with suppliers, which streamlines the design process and reduces time-to-market.

The benefits of AI-assisted selection of products and components extend to both engineers and suppliers. Engineers can focus on core design challenges, while suppliers gain insights into demand trends. Also, engineers can use these tools to collaborate more efficiently with design teams. The result is a more agile, responsive, and innovative engineering ecosystem.

Generative AI and Design Optimization

One of the most prominent industrial use cases of Generative AI is the rapid generation of alternative design options for products and components. In the scope of such use cases, GenAI uses machine learning to autonomously create and optimize design alternatives based on specified constraints and goals. This is very important in industries such as automotive, civil, and mechanical engineering, where Gen AI is enabling the creation of novel, efficient, and sustainable designs. Most importantly, the creation of these designs takes place faster than ever before. For example, AI-driven simulation tools allow engineers to rapidly validate designs, which reduces the need for costly physical prototyping. Furthermore, such simulation tools can provide real-time feedback on the performance and manufacturability of the prototypes.

Case studies in the above-listed sectors demonstrate that generative AI can lead to breakthrough innovations, such as lightweight automotive components, optimized building structures, and energy-efficient mechanical systems. Overall, GenAI endows modern engineers with the superpower of exploring a vast design space very quickly and efficiently. This is set to transform traditional engineering workflows.

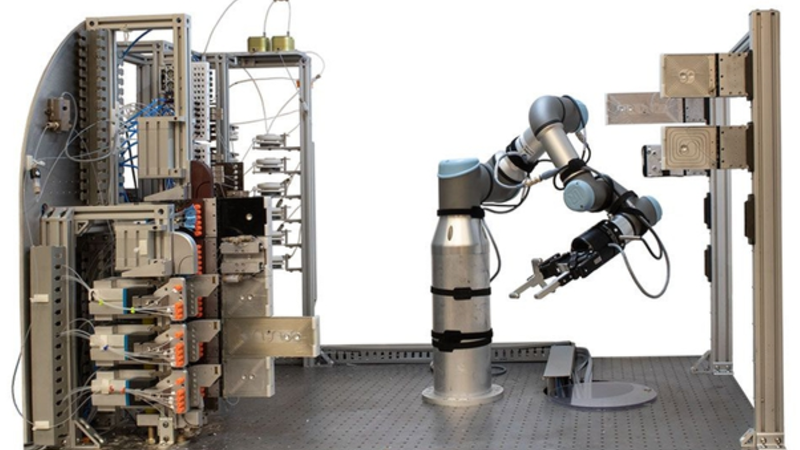

AI for Predictive Maintenance and Operations

AI has been also revolutionizing maintenance strategies through predictive analytics. Specifically, AI algorithms have enabled a shift from conventional maintenance paradigms that lead to sub-optimal utilisation of critical assets (e.g., preventive maintenance) to CBM that aims to maximise the useful time of the asset in ways that lead to the best possible overall equipment efficiency (OEE). To this end, condition-based monitoring leverages sensors and other information in order to track and assess the actual condition of the asset prior to taking any service, maintenance and repair decisions. One of the most effective strategies in this direction is predictive maintenance, which leverages sensor data and machine learning to predict equipment failures before they occur. This enables proactive CBM in ways that maximize OEE and minimize unplanned downtime. Relevant AI-based implementation workflows typically involve data collection from IoT sensors, feature extraction, model training, and real-time monitoring.

In recent years, GenAI has boosted the development of predictive maintenance strategies through facilitating data analysis and the production of algorithms that estimate remaining useful life (RUL) and schedule maintenance activities. Most importantly, GenAI models can help with the generation of synthetic data whenever there is a lack of adequate volumes of historic data for predictive maintenance. Furthermore, the use of GenAI models (such as LLMs) can reinforce the contextual relevance of the maintenance strategies and predictions, leveraging on the vast training datasets and knowledge of the LLMs. Also, the use of state-of-the-art GenAI models can boost the development of multimodal capabilities that combine different types of data in order to produce more accurate and credible RUL predictions.

The benefits of AI-driven predictive maintenance are already substantial. They include reduced maintenance costs, minimized safety incidents, and improved operational efficiency. Based on AI and GenAI, industrial organizations can optimize resource allocation, extend equipment lifespans, and ensure higher levels of safety and reliability.

Future Outlook: Accessible AI Tools for Every Engineer

Overall, the democratization of advanced AI tools is empowering engineers across disciplines to leverage cutting-edge capabilities without requiring deep expertise in machine learning or data science. In the AI era collaboration and knowledge sharing are becoming much easier than in the past, as AI-driven platforms facilitate seamless communication and integration across teams and organizations.

Nevertheless, the AI landscape is still not free of challenges. For instance, AI adopters must deal with data quality issues, as well as with human worker’s limited trust in AI recommendations. To alleviate these issues there is a need for human oversight in AI processes. Moreover, regulatory compliance and ethical concerns must be addressed as AI becomes more deeply embedded in engineering workflows. Despite these challenges, the future of AI-based engineering design is bright. In the near future a richer set of accessible, intelligent and powerful tools will enable innovation at lower costs and shorter timescales.