Do you know Polyjet 3D Printing Technology?

You might know about resin 3D printing but do you really know Polyjet technology? This manufacturing technique could be attractive for your company for the creation of proof of concept or realistic prototypes. Discover what Polyjet is!

Tags

You might know about resin 3D printing but do you really know Polyjet technology? This manufacturing technique could be attractive for your company for the creation of proof of concept or realistic prototypes. Discover what Polyjet is, how it works and how it could become an asset for your manufacturing process.

If you are looking for a way to print your Polyjet parts, don’t forget that Sculpteo is offering a Polyjet 3D printing service!

Polyjet 3D printing: What it Polyjet?

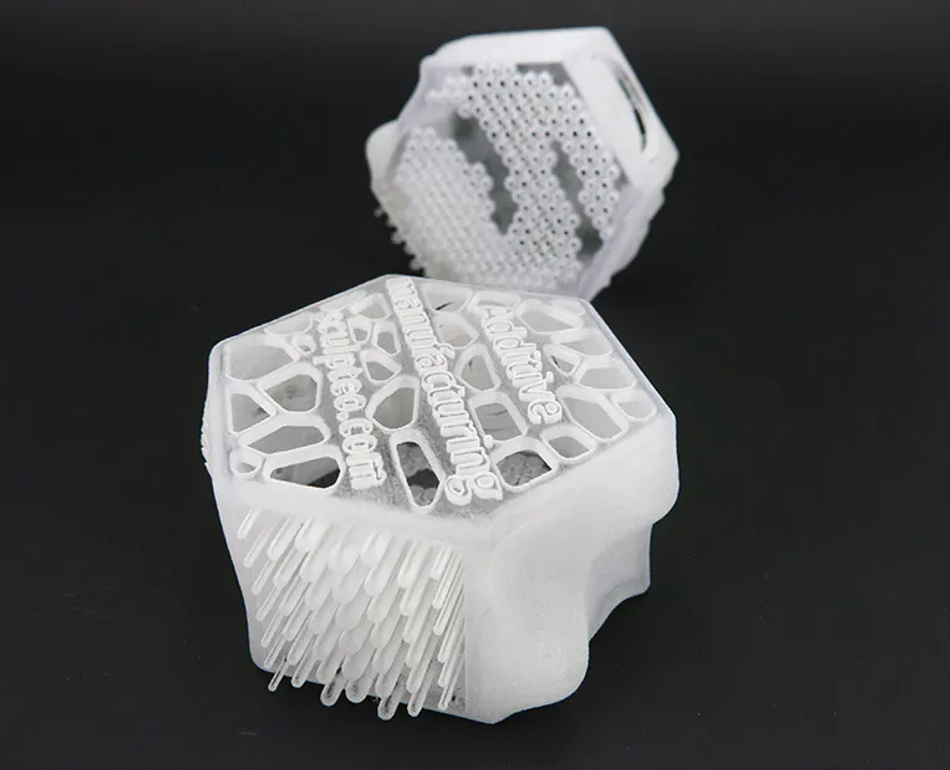

PolyJet 3D Printing is a industrial manufacturing method. PolyJet 3D Printers work similarly to inkjet printers, but instead of jetting drops of ink onto paper, they jet layers of curable liquid photopolymer onto a build tray.

The software automatically calculates the positioning of photopolymers and support material from a 3D CAD file during pre-processing; when printing, the resin 3D printer jets and instantaneously UV-cure tiny droplets of liquid photopolymer.

The Polyjet 3D printer fires a detachable support material called FullCore 750 where overhangs or complicated geometries require support. The fine layer polymerization process is repeated until the object is complete.

Following the completion of photopolymerization, the batch is subjected to a pressured water jet. With a few human contacts, any extra liquid or supports can be eliminated.

The finished product has a naturally smooth surface that can be polished further to achieve near-complete transparency for the transparent resin. After cleaning, 3D printed objects and parts are ready to handle and use. Post-curing is not required.

What are the advantages of Polyjet technology?

PolyJet technology is known for its great surface finish, which allows to create detailed and smooth prototypes. This manufacturing technology is popular for rapid prototyping because of its excellent precision to CAD files. This resin technology can create detailed features, complex shapes, and delicate characteristics. Its an efficient technique, which incorporates a wide range of materials and colors into individual models.

Some resin materials available with the Polyjet technology offer a rare characteristic. Indeed, the VeroClear material, that we will see more into details after, has the adaptability to become transparent after polishing.

What are the applications of Polyjet 3D printing ?

PolyJet 3D printing technology is used in a variety of applications across several industries due to its high precision, high accuracy, and high-resolution surface quality. PolyJet technology is a versatile 3D printing technology that offers a wide range of material options, allowing for the production of parts with different properties, such as transparency, flexibility, and strength, making it suitable for a variety of applications.

Some of the common applications of PolyJet technology are:

- Product Design and Prototyping: PolyJet technology is widely used in product design and prototyping, as it allows for fast and accurate testing of designs.

- Medical and Dental: PolyJet, when used with some specific materials, can be used for the production of medical and dental models, surgical guides, and implants. It allows for the production of highly precise and accurate models for pre-surgical planning and for testing of medical devices.

- Automotive: PolyJet technology is used for the production of automotive prototypes, including interior and exterior parts, as well as for testing and validation of automotive designs.

- Consumer Goods: PolyJet technology is used for the production of prototypes and end-use parts for consumer goods, such as electronics, toys, and household appliances.

- Art and Jewelry: PolyJet technology is used by artists and jewelry designers to create intricate, high-quality prototypes and finished pieces.

What are Polyjet 3D printing materials?

Sculpteo’s online 3D printing service is offering two different resin 3D printing materials:

From a substrate of liquid photosensitive polymer, 3D printed items are produced using our VeroWhite Resin substance (opaque PolyJet resin). Layer by layer, that liquid is then hardened by UV radiation to produce 3D prints that are as rigid and finely detailed as injection-molded plastics. While using VeroWhite 3D printing material, the finished item has a surface that is naturally smooth and opaque.

Our VeroClear resin (translucent Polyjet resin) creates 3D printed items using photosensitive polymer liquid. VeroClear 3D printing gives you access to fantastic features, difficult to obtain with other 3D printing materials. VeroClear is initially translucent, but you can increase its transparency by polishing your part yourself or using one of our polishing finishings. The finished item has a naturally smooth surface that can be further polished to achieve almost complete transparency!

But the Polyjet technology can actually print a lot of other different 3D printing materials such as flexible photopolymers, bio-compatible photopolymers or composite photopoymers.

Polyjet vs SLA: Comparison and differences

SLA and Polyet are often seen as the best options to create detailed objects with a smooth surface, they both have an important role on the 3D printing market. These two technologies are resin-based and employ a UV-cured liquid resin, however, their printing processes are quite different.

As the platform is lowered into the resin tank with each pass, SLA employs a laser to imprint a layer on the resin tank’s surface. A UV lamp is used to cure each layer when the object is produced in. On their side, PolyJet printers build up a 3D model by spraying tiny droplets onto a dry construction plate. With PolyJet 3D printers, the resin is distributed onto the print bed using an inkjet-like print head.

Ultimately, the choice between Polyjet and SLA depends on the specific applications and requirements. Depending on the materials you choose with these technologies, you won’t necessarily obtain the same properties. Polyjet might offer a better resolution, as well as a more diverse offer in terms of materials and colors.

Going further: An introduction to resin 3D printing

Resin 3D printing is commonly used in industries such as medical and dental, consumer goods, jewelry, and more. It is also used in the production of prototypes, end-use parts, and molds for casting. Polyjet is not the only resin-based technology. For example, here are the different options you can use by working with Sculpteo’s online 3D printing service:

- Stereolithography (SLA)

One of the earliest 3D printing processes ever created is stereolithography (SLA). In this method of additive manufacturing, resin material is 3D printed using a photochemical process.

This SLA 3D printing process cures the liquid photopolymer resin in a vat. When the build plate is moved incrementally, the liquid polymer is exposed to light, and the UV laser exploits this exposure to generate a cross-section. Up till a model is created, this layer-by-layer procedure is repeated. The liquid, uncured resin at the bottom of the container can be utilized to build the object’s next layer when the bottom-up object is removed from the resin.

- SLA 3D printing materials offered at Sculpteo: Prototyping resin.

- LCD printing

The resin tank flashes entire layers at the UV light source, which is an array of LEDs shining through an LCD. The entire image is hidden behind a screen so that only the layer that has to be cured is visible. A cost-effective resin production method for large, intricate functional parts is LCD 3D printing. Thanks to 3D printers with larger build trays created by companies like Photocentric, this 3D printing technique concentrates on mass production and large component 3D printing for resin materials.

- DLP printing

The light source for DLP 3D printers is a digital light projector. A semiconductor chip matrix with tens of thousands of micromirrors makes up the DMD (Digital Micromirror Device). The digital light projector’s projected light beam is navigated by these micromirrors.

- DLP/LCD 3D printing materials offered at Sculpteo: Ultracur3D® EPD 1086, Ultracur3D® RG 35, Ultracur3D® ST 45, Ultracur3D® ST 45 B

- CLIP (DLS)

CLIP is a printing technology developed by Carbon. It works by projecting a continuous sequence of UV images, generated by a digital light projector, through an oxygen-permeable, UV-transparent window below a liquid resin bath. The dead zone created above the window maintains a liquid interface below the part. Above the dead zone, the curing part is drawn out of the resin bath.

- CLIP/DLS 3D printing materials offered at Sculpteo: Rigid Polyurethane, Elastomeric Polyurethane

Are your looking for a Polyjet 3D printing service?

Working with a resin 3D printing service will offer you many benefits. First of all, you won’t have to deal with your own 3D printer. You just have to upload your model, choose your technology and 3D printing materials, it will only take a few click to get your instant 3D printing quote. We will take care of all the details for you and send your parts once they are ready.

Our 3D printing experts can help with your 3D printing project. Contact us for any question!

If you are looking for some help to design your 3D file to print them with Polyjet, we recommend to contact our design studio, Sculpteo Studio.

Tags