About

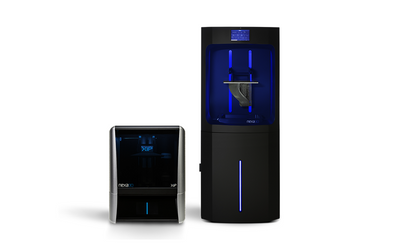

With 13 years of experience in additive manufacturing, Lewis is passionate about 3D printing for prototyping and production applications and driving awareness for end-use part production with this innovative technology. He started his career in project engineering for Harvest Technologies (acquired by Stratasys in 2014) where he worked directly with clients on projects across aerospace, defense, consumer products before moving into product marketing for contract manufacturing services. Lewis now serves as Vice President of Global Marketing for Nexa3D.